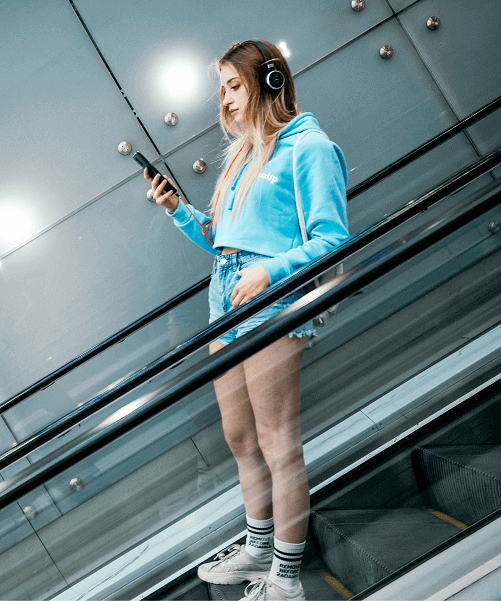

We have been making clothes for many years, but hoodies are our flagship products. Over the years, we have managed to refine every detail to meet our customers’ expectations for the highest quality. It would seem that it is just a simple hoodie. However, in this article you will learn how many factors contribute to the final product with supreme quality – a hoodie that looks as good as it feels!

Fabric (raw material) – composition, origin, and material weight.

Technically speaking, the fabric from which hoodies are sewn is called knitted fabric. We must admit that when we started our business, we used ready-made fabrics bought off the shelf from a wholesaler. After some time, we decided to launch the production of custom knitted fabric.

What does it mean? All the hoodies colours, as well as the thickness of the fabric, were made according to our demands. Burgundy finally became burgundy, not dirty red, and navy blue finally became navy blue.

The composition of our knitted fabric is 90% cotton and 10% polyester. While 100% cotton is often used for t-shirts, this is not possible for hoodies. The knitted fabric used for hoodies should have a small addition of polyester so that it does not wear out quickly (e.g. in washing).

The weight of the knitted fabric (280g/m2) was optimally selected, so that the hoodie can be worn under a jacket/coat in winter but is also suitable for summer evenings. If necessary, we can also make hoodies with different weight and composition of the knitted fabric. The knitted fabric is made in EU in line with OEKO-TEX 1000 standards. On request, we can also produce hoodies made from organic yarn that complies with GOTS (Global Organic Textile Standard) standards.

Sweatshirt trimming – double stitching, metal elements, and thick cords

As promised, we’re breaking down our hoodie piece by piece. There are small details that make our hoodies stand out so much in terms of quality. Over the years, we have established cooperation with the best suppliers of threads, zips and snaps for baseball jackets.

The first modification we have introduced in the production of hoodies is double stitching, which you can see e.g. at the elastic bottom hem. This not only makes the hoodies look and feel better, but also prevents the hoodie from constantly “rolling up”.

Another advantage of our hoodies are quality details, such as metal snaps in baseball jackets or zips in zip up hoodies. It took us a long time to find the right supplier of cords for hoods, but we have finally succeeded in getting exactly what we wanted.

Branding – embroidery/screen printing

School, company or university logo on a hoodie is an element that makes the hoodie stand out and gives a sense of belonging to the community. Usually such a logo is placed on the front of the hoodie. Depending on the customer’s preferences, logos are made using computer embroidery or screen printing.

Is the print really durable? This is a question we hear very often from customers. Screen printing is a printing method which is virtually INDESTRUCTIBLE and does not fade in any way during washing or wearing. Screen printing is often confused with other printing methods, such as digital printing, which is not so durable. What’s more, we make our prints using acrylic paints, which are safe for children.

The quality of BluzUp!

This means… EU production + high-quality fabrics + precise execution.

We hope this article was useful and helped you see how much we care about the quality of our products. If you still have any doubts and think about ordering corporate/school clothing from us, we can send you a free sample products you are interested in.

Would you like to get to know us better? Go ahead and click below!