You made up your mind – you want to order a hoodie. You have a design, but you’re unsure what printing method would be the best. There are so many of them described on the internet. But unfortunately, it doesn’t help; it only adds to the confusion.

Lucky break, you are now in the right place. This article will describe the three best and most durable printing methods.

What are the differences between the three most popular printing methods?

We know from experience that choosing the type of print may be troublesome for people outside the industry. Look at the methods that we always suggest to our clients:

Screen printing

This is the most durable and technologically simplest printing method. After receiving the design, we make a stencil on a woven mesh screen. We then put the stencil on a hoodie and apply the paint. The paint passes through the mesh only in places designated by us, creating a vibrant and durable pattern.

You should know that one stencil means only one print color. If you have a project with multiple colors, you will need another stencil for each of them. That is why we recommend screen printing for one- or two-color projects. This method won’t allow transitions of colors (gradient) as you can only apply one paint at a time.

Nevertheless, screen printing can be used on fabric in any color, and allows you to match the shade to your company’s visual identity perfectly. Using screen printing, much like embroidery, you can achieve unusual effects. We can use special paints for printing, e.g., glitter, metallic sheen, glow in the dark, etc. By making a puff print, we can also obtain a 3D effect.

Screen printing will work well with most materials and surfaces. At BluzUp, 30 pieces is a minimum order for this method.

DTG printing

Another very durable and common method of printing is DTG (Direct-to-Garment). A special printer applies the ink directly to the fabric. It is similar to printing we know from home or office. The entire process takes a few minutes, depending on the project’s complexity. Unlike embroidery and screen printing, DTG printing does not require complex preparation, like a program or a stencil. Color reproduction is very accurate when printing on light fabrics. However, printing on dark items may require a white base coat. DTG allows you to choose from a vast range of colors and gradients.

With DTG, you can print very detailed and high-resolution graphics. It’s also the only method that allows you to reproduce photos on the fabric. Contrary to embroidery or screen printing, the DTG print would be imperceptible to the touch. We use this method on fabrics that are at least 50% cotton.

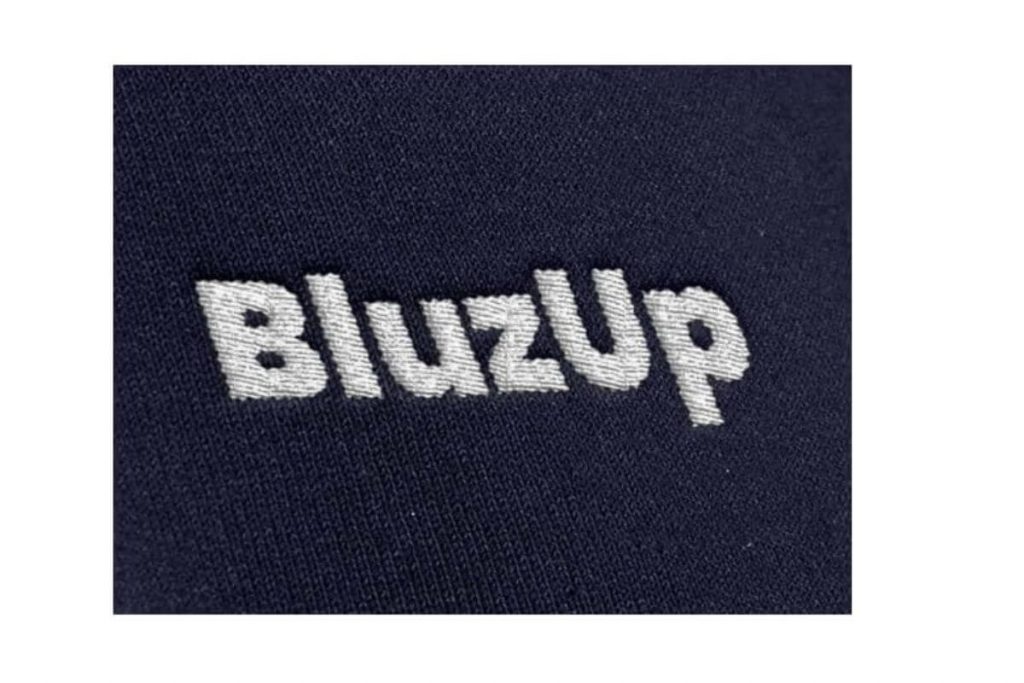

Computer embroidery

Of course, embroidery is not a print. We include it in this list, as it’s an excellent method and a common choice among our clients.

Embroidery is made by a machine. To make it possible, we have to create a unique computer program. Unfortunately, not every design is suitable for embroidery, e.g., due to the high level of detail.

Using this method, you can use any colors and obtain unusual effects such as:

– three-dimensional (puff, 3D embroidery),

– the illusion of, e.g., metallic sheen (use of metallic threads),

– the effect of a fluffy rug (chenille embroidery).

With embroidery, you can decorate thick outerwear. It is often used on hats (beanies, baseball hats) and scarves. That is a significant advantage of embroidery as printing (screen printing, DTG) on large weave fabrics is impossible.

This is also the only method that will work on an uneven surface, e.g., on fabric with an embossed pattern.

Generally, embroidery is considered exclusive and prestigious, but it also has some flaws. For example, it can be damaged if you accidentally pull a thread from it. Furthermore, embroidery made on the entire front of the hoodie stiffens it, and made on a thin T-shirt can irritate the skin.

Thankfully, creating a program for an embroidery machine is a one-time cost, so you pay the same amount no matter the volume of your order.

Screen printing | DTG printing | Embroidery | |

|---|---|---|---|

The fabric on which the print is made | any | cotton or cotton-rich | any, except for very thin ones |

Image reproduction | great with low detailed graphics | great with very detailed graphics/photos | complicated graphics require simplification |

Number of colors in one print | max 7 | no limit | max 15 |

Color reproduction | perfect color reproduction | perfect color reproduction | requires thread color selection (from a wide range) |

Gradient | no | yes | no |

Three-dimensional | yes | no | yes |

Unusual effects | – special inks (e.g., glitter, in-dark-glow, metallic sheen) – puff print | none | – special threads (e.g., metallic) – 3D embroidery – chenille embroidery |

As you can see, each method has its traits and flaws. To choose the perfect one, we analyze the design, your preferences, and the purpose of the hoodie. We do not require our clients to specialize in the subject and choose the method themselves. We are always happy to advise the best type of print for your project.

Can my logo be made with any of the available technologies?

Unfortunately not, for each logo, we have to choose a suitable method. For example, we will not embroider a very detailed logo or print it on a polyester bag using the DTG method. However, small changes to the project may help achieve the desired effect. At BluzUp, we will help you by simplifying the logo or changing the fabric for better-suited one. Alternatively, we will advise you on the best replacement for the selected printing method.

We make clothes ourselves so we can print on elements before sewing them together. This is why in BluzUp, you can place your logo anywhere you want.

To learn more about how we make our hoodies read the article here.

Also, remember that the size of the logo is very important for the final effect. It may turn out that the design looks great in a large format, but as a ready, five-centimeter print, it is illegible. In BluzUp, we make prototypes to ensure the finished product will meet your expectations.

Will the order volume affect the production time?

Preparation of production is the most time-consuming and challenging element of the process. It includes: designing a pattern, selecting colors, methods, materials, and programming machines, or making stencils. Printing itself is a quick process. Therefore, the order volume does not significantly affect the production time.

However, it is worth mentioning that you significantly impact the production time as a client. At the consultation stage, you will select a model, fabric, and then accept the visualization. Later in the process, we will need you to accept the prototype as well. The sooner you provide us with the necessary information, the faster we will start production.

If you’re not sure how to choose the right sweatshirt for your employees, check out this article.

To sum up:

At BluzUp, we print hoodies with the three best (in our opinion) methods:

– screen printing

– DTG printing

– embroidery

We always help our clients choose a method best suited for their project. Regardless of which type of printing you choose, you will receive the finished product within 30 business days (except for huge orders).

If you found this topic interesting and want to learn more about the process of making and ordering custom clothes, have a look at this article.

Dodaj komentarz

You must be logged in to post a comment